OEM

ABOUT

In 1969, starting the business relationship with A Barker & Sons in Northamptonshire, England, we have accepted a commissioned manufacturing for Nihonseika Co., Ltd.

Since then, we have been improving our skills for satisfying the client’s needs.

Since 1990, we have been proposing ideas based on the knowledge of shoe maker which fit for various materials and unique designs.

In recent years, we have helped more than a hundred clients to put every ideas into shapes by our proposal, skills and productivity.

We will supply you reliable products made in Japan by the consistent domestic production.

Also, we promise you good quality products and a shorter delivery time, based on the production with agility.

The core concept of our OEM business is “Realized by Miyagikogyo” and we shall strongly support your business.

FLOW

1.CONTACT

Please contact our OEM business section first.

Feel free to tell us what kind of shoes and which construction method you like.

2.CONTRACT

We need to examine your application before starting business with you.

We basically ask a new client Cash On Delivery for the payment.

Then, we have to confirm and agree the terms and condition.

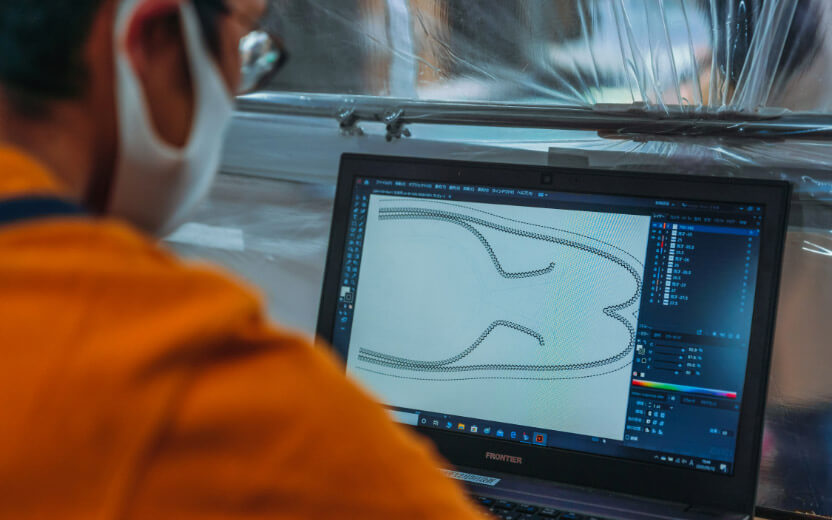

3.SAMPLE

For sample making, our professional staff offers ideas of last, materials and construction methods based on the design pictures or sample shoes.

4.SPECIFICATION

We keep improving designs or patterns until you get satisfied with the sample.

5.QUOTE

After we finish making the sample and specification sheet, we offer you a quotation.

6.ORDER

Once you are satisfied with the finishing and quotation of shoes, we accept your order.

7.PRODUCTION

All the process will be done by the professional staffs and craft workers, according to the specification sheet.

8.DELIVERY & SUPPORT

We deliver the items to the address you mention after the inspection.

If by any chance some problem happens, we will immediately deal with it as much as we can.

We would be happy to have feed backs from you and end users.

METHOD

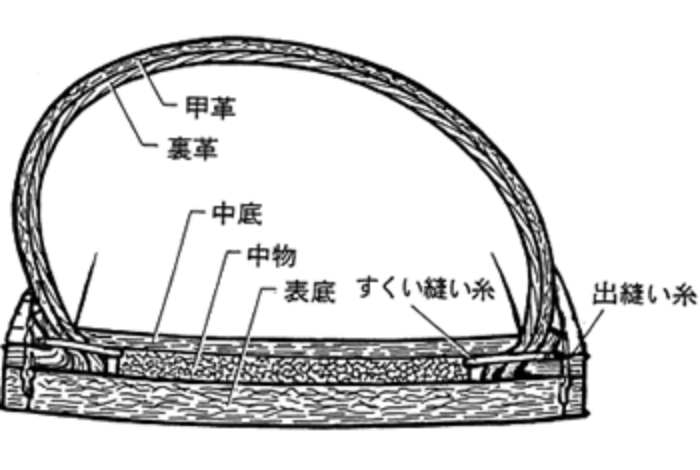

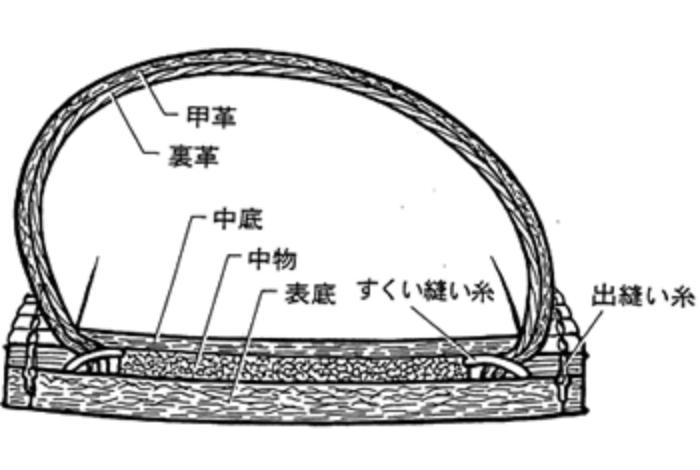

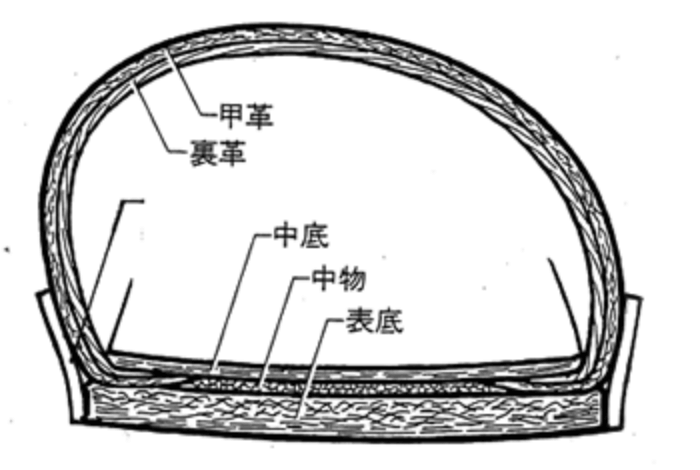

Good year welt construction

Features

- Durable. Resoling is available.

- The traditional method and looks classy.

Fitting

- Well cushioning.

- Nicely fits on your feet because of the cork inside.

Suitable shoe types

- Dress shoes

- Work boots

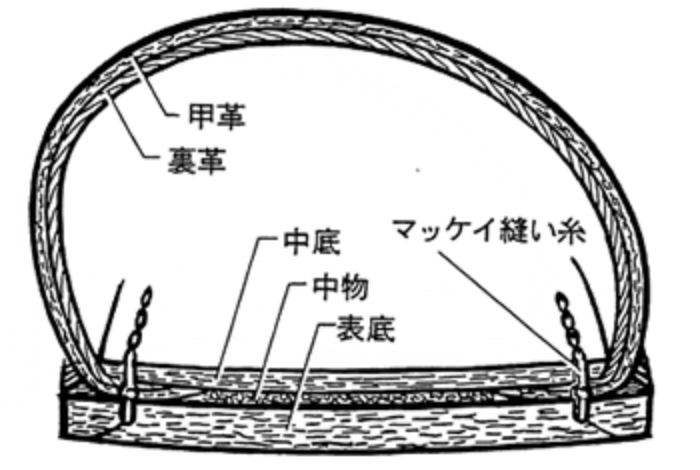

Blake stitching (Mckay process)

Features

- Available for several designs.

- Because of the thinner sole, shoes get lighter and more comfortable to wear.

Fitting

- Light weight and well bouncing.

- Breathable.

Suitable shoe types

- Business shoes

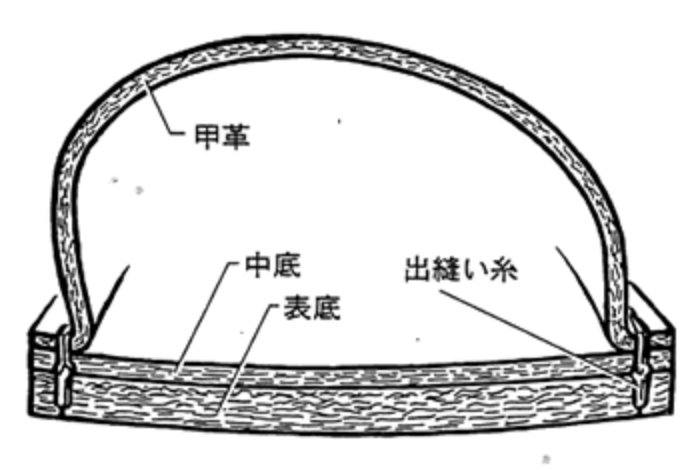

Stitch down process

Features

- The upper widening towards outside makes the shoes look casual.

- Comfortable. Easy to walk in.

Fitting

- Light weight and well bouncing.

Suitable shoe types

- Comfort shoes

- Casual shoes

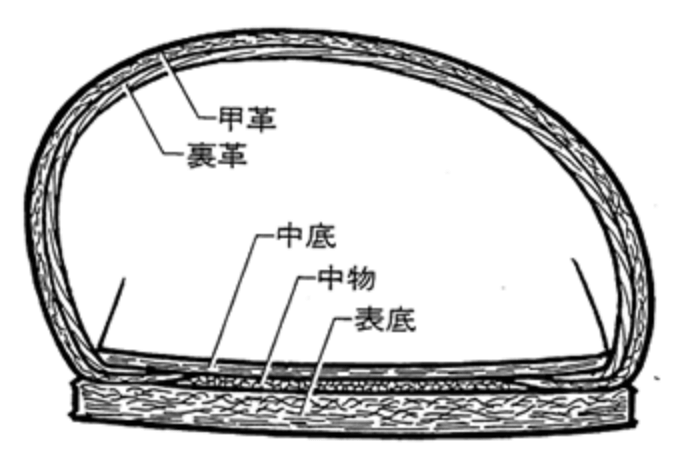

Cemented construction

Features

- Available for several designs.

- Water resistant and comfortable fitting.

- Cheaper cost than any other methods.

Fitting

- Light weight and well bouncing.

Suitable shoe types

- Business shoes

Mudguard

Features

- Highly water proof, because a rubber or leather wrapped from the out sole to the upper.

Fitting

- ight weight and well bouncing.

Norwegian

Features

- Higher water resistance than good year welt construction.

- Solid, but causal appearance.

Fitting

- Well cushioning.

- Nicely fits on your feet because of the cork inside.

- Highly water proof.

Suitable shoe types

- Climbing boots